Pump & Systems – pump optimization software

Process Energy Services is pleased to introduce PUMP & SYSTEMS “BASIC” AND “PRO”, the new software tools created to assist facility operators and engineers optimize existing and new pump systems to improve efficiency and reduce energy costs.

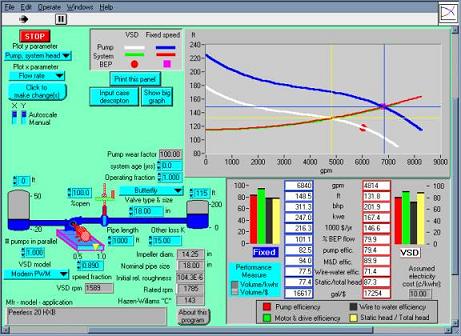

The PUMP & SYSTEMS software tools are designed to take the mystery out of centrifugal pump systems, and help identify opportunities to improve pump efficiency and reduce costs. This program is ideal for modeling water and wastewater pumps, cooling and chilled water system pumps, and process pump systems.

The benefits of PUMP & SYSTEMS software includes:

- The ability to model an existing pump by inputting pump curve data specifically for the pump being reviewed.

- Allows the user to evaluate the efficiency of multiple pumps operated in parallel

- Provides energy cost comparison for operating a pump at full speed or reduced speed with a VSD

- Evaluates the energy cost impact of the following system changes:

- Pipe size

- Pipe length

- System age

- Tank levels

- Fluid temperature

- Motor efficiency

- Energy Cost

- Type of variable speed drive

- Easy to use pull down menus that allow the user to enter information for pipe sizes, valve types, tank elevations (or static head), motor efficiency, cost of electricity and other parameters to evaluate pump system energy costs.

- A visual representation of the pump, piping and tank system, a simulated pump curve, and a detailed efficiency comparison list for operating the pump as a fixed speed or variable speed pump (Basic).

- The ability to model fixed or variable speed multiple pumps operating in parallel to determine system head and flow output as well as the optimum speed and number of pumps to operate the system as efficiently as possible (Pro).

For more information see PUMP & SYSTEMS web page.

Please send me detail information.

Thanks

Please send me more details. I am interested in the Software